Description

The next generation IMER Koine 4 continuous mixer – pump is the big brother of the IMER Koine 35, and designed to give more volume and production. The Koine 4 is used almost exclusively for mixing and pumping wall grouts and self-leveling underlayments for those projects where you need tremendous production.

The Koine 4 can dramatically cut down on your labor as it can easily handle the work of 2-3 mixers and runners walking with buckets back and forth hundreds of feet each way. Just set the water volume to the desired consistency, keep feeding it bags and let it run. Every bag will be consistent from start to finish with no cold joints.

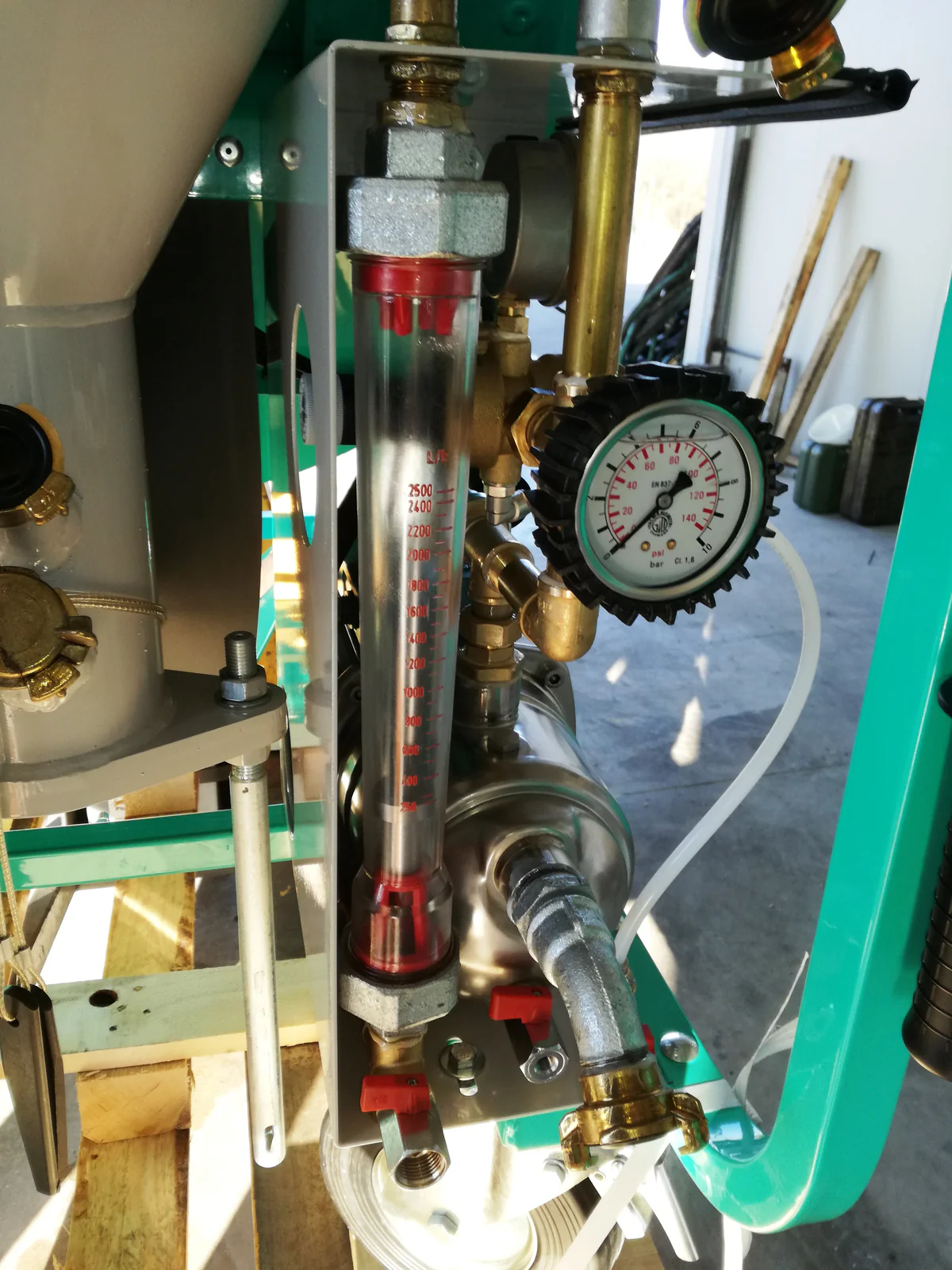

A 7.5hp, 220V, 3 phase motor drives the gearbox, main shaft, mixing paddle, rotor, and standard turbo mixer. An upgraded 1hp water booster pump is included to boost the water pressure and flow and also siphon water from a tank if needed. Boosting the water provides a surplus in which a regulator injects the water into the mixing chamber at a controlled rate. The water booster pump is also used to flush out the hoses so that your quick setting materials do not set up. Insert a sponge ball, connect the hose, open the valve and catch the sponge ball on the other end. This flushes out and cleans your hoses in under a minute.

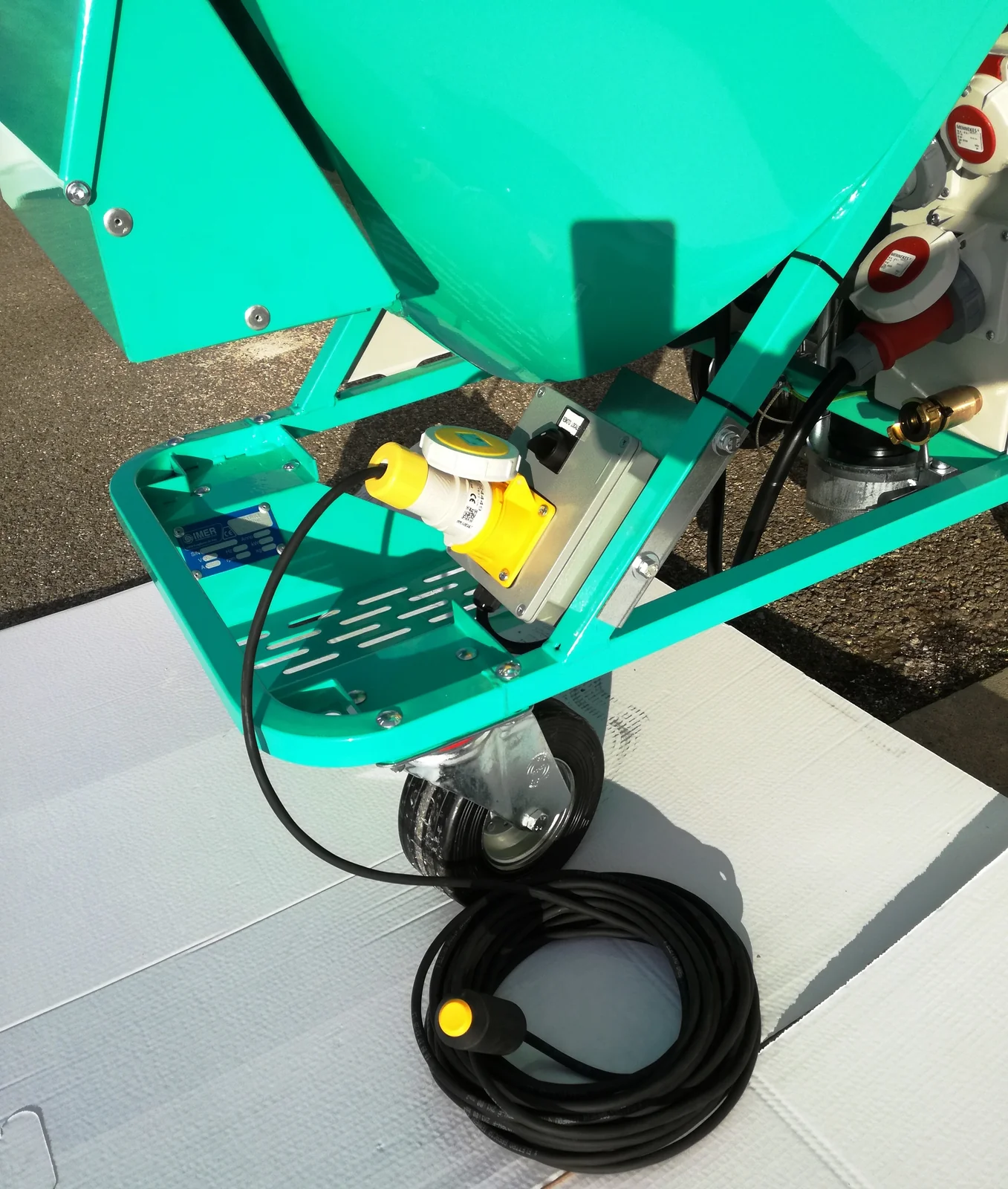

An optional wired remote control is available with the Koine 4 to allow the start and stop of the pump from over 100′ away. This comes in handy when you need to see how much flow is filling up your void or floor.

The hopper and feeding wheel can handle up to 9 – 50 lb.bags of dry material at one time, delivering dry material at a constant rate to the mixing chamber to be mixed and then pumped out. If you need to stop for a break or end of day you can leave the dry, unmixed material in the hopper – just switch off the feeding wheel and use out what is in the mixing chamber.

The new upgraded Koine 4 comes standard with a R8 rotor and stator, turbo mixer with pressure gauge, toolbox, cleaning tool, 33′ of 35mm hose, power cord, water hose and miscellaneous parts and connections. Add more hose to get closer to where you need the material.

If the situation arises, a optional dual diaphragm compressor can be added as well as a gun kit as the unit is plumbed for it. The compressor is used to spray mortars, stucco, plasters, etc.

Features

- Gear driven continuous feed impeller wheel provides dry material to mixing chamber

- Dust control grate with vacuum port helps eliminate dust.

- Upgraded self priming water pump can pull water from external tank, no water hook up required.

- Upgraded 2500 liter per hour water system allows for precisely metered flow for different materials based on requirements.

- Once set up with the correct water flow for a particular material the water system will deliver the same mix all day long.

- Easy clean up mixing chamber with different material paddles available

- Switchable 3 phase connection via phase converter switch for forward and reverse

- Only 27 inches wide to fit thru any doorway

- Pump up to 300+ feet away.

- Pump self leveling underlayments or fill blocks with grouts.

- Three phase 220v, 7.5 hp motor with 410 RPM gear reduction drive system to the paddle

- Low 36″ hopper loading height

Specifications

| Specifications | Koine 4 |

| Power supply | 220v 3phase |

| Total machine power HP | 9hp |

| Mixing and pumping motor HP | 7.5 |

| Feeding impeller wheel motor HP | 1 |

| Electric compressor 1HP- 9cfm V-stroke | Optional |

| Variable speed material flow | No |

| Material flow rate cubic feet per hour | 169 CFH |

| 50lb bags per minute flow rate | 5 – 7 |

| Maximum pumping distance 35mm (1-3/8″) hose feet | 300+ |

| Hopper capacity 50lb bags | 9 |

| Loading height inches | 36 |

| Dimensions width/length/height | 29″/47″/61.5″ |

| Weight | 475 lbs. |

Reviews

There are no reviews yet.